Step 1: Confirm your need and place a trial order (2-7 days)

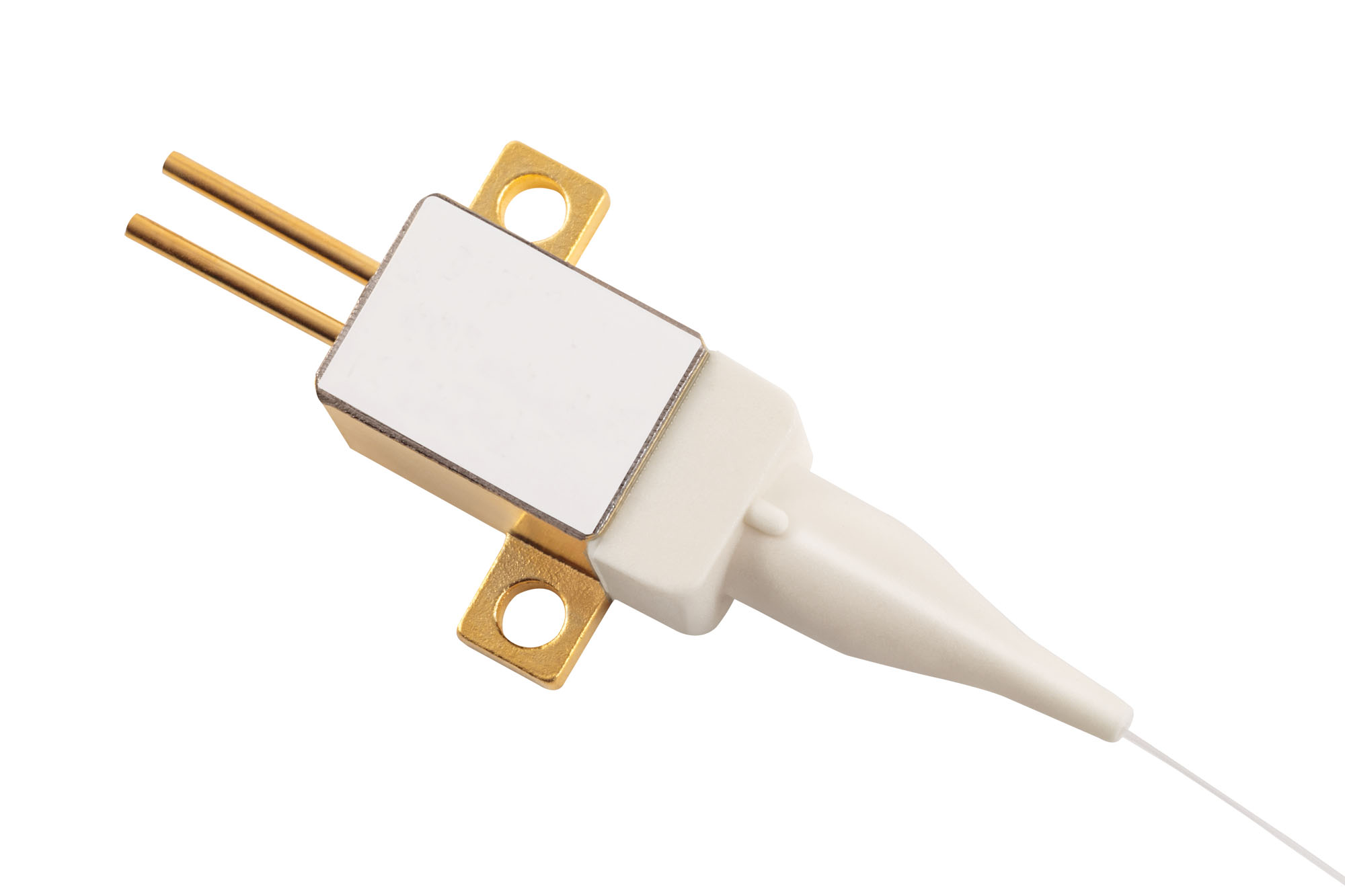

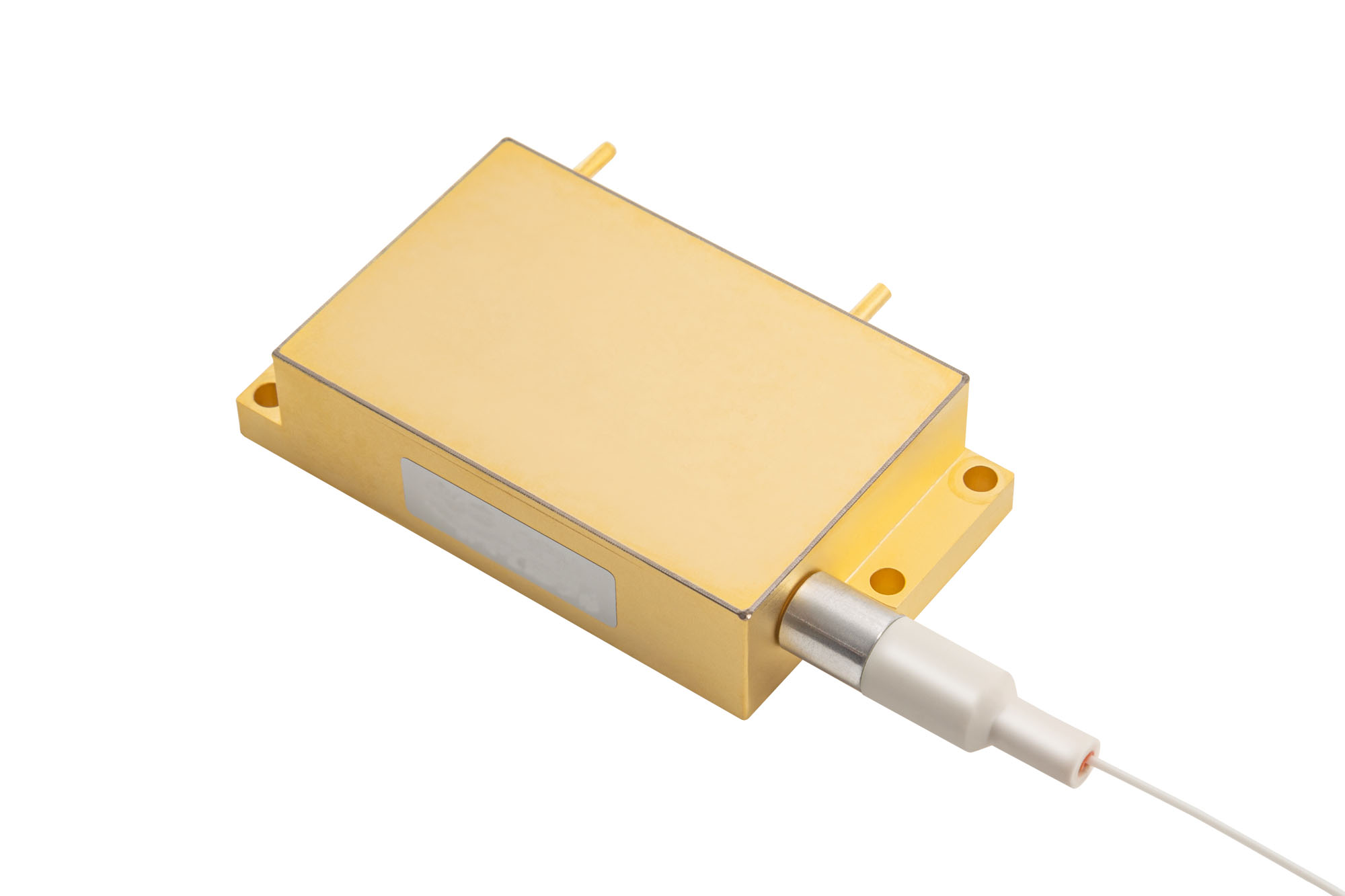

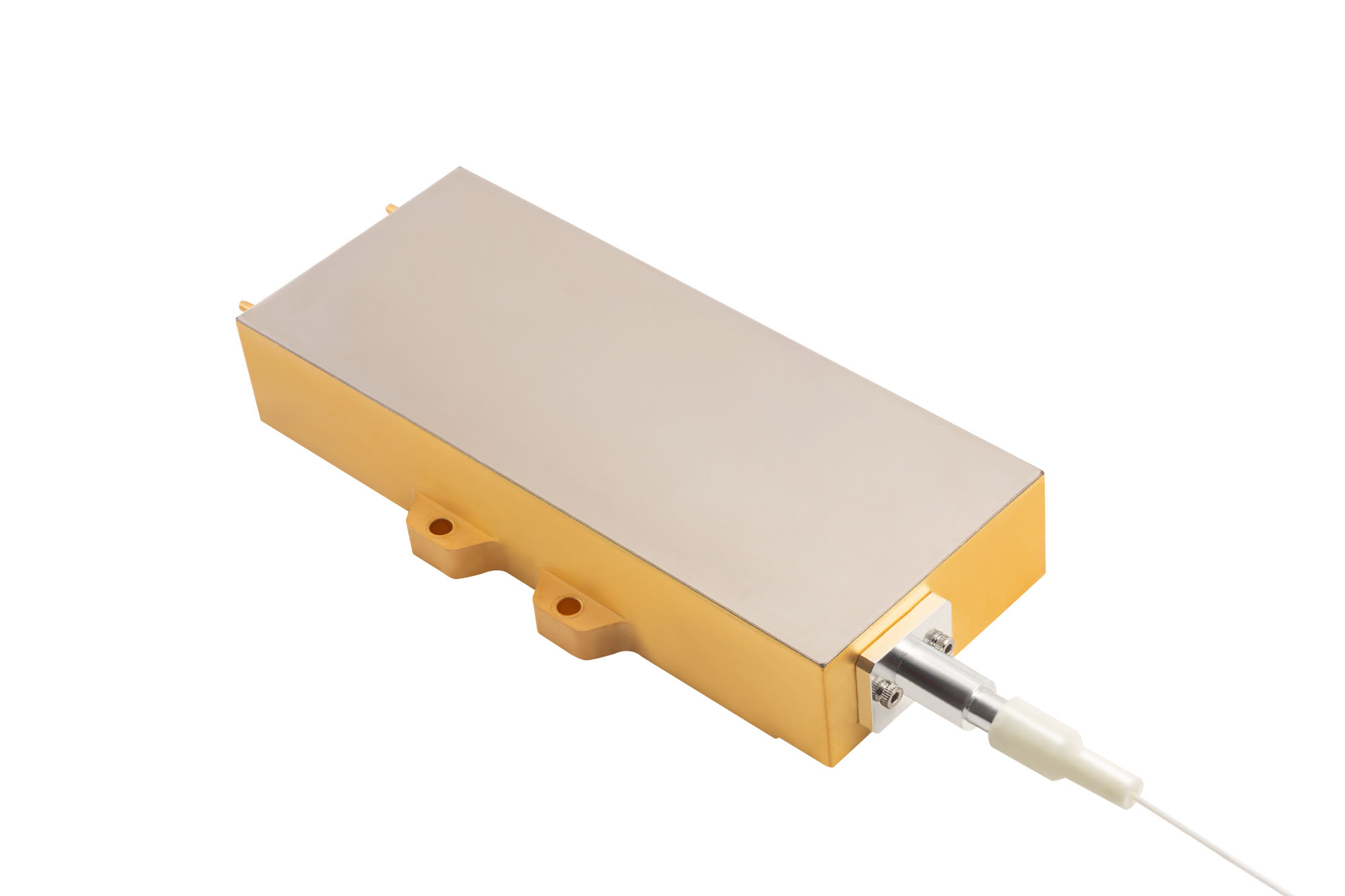

We’re here to listen, guide, and assist, ensuring you identify the right LD for your applications. Our experts review the required product packaging type, and select products according to needed parameters such as wavelength, power, fiber diameter and numerical aperture. It usually takes 2-7 days from confirming the model to releasing the P/I.